Advanced Thermal Optics by Coatmaster

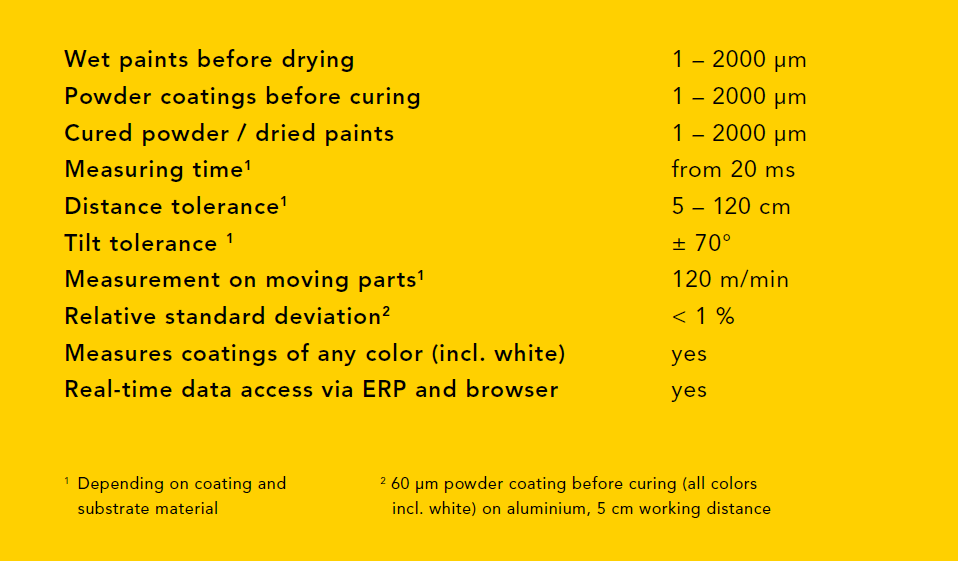

With Coatmaster technology (ATO), layer thickness can be measured immediately after coating thickness is applied. The technology works without contact and non-destructive hazardous emissions and is suitable for coatings on metal, paper, rubber, ceramic, glass, plastic and wood surfaces, among other things.

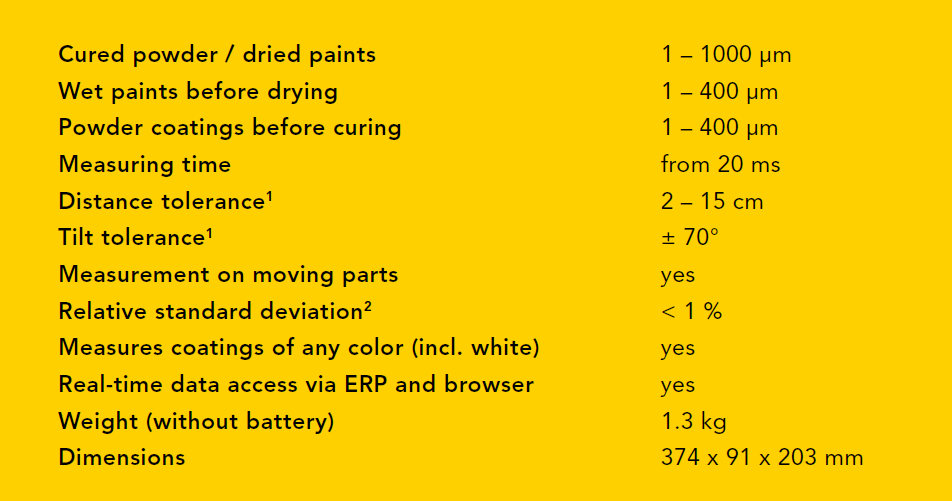

Mobile solution for non-contact layer thickness measurement.

Handheld device manager Flex just grab it and start measuring.

This mobile handset is the innovation in the field of non-contact layer thickness measurement.

Would you like to measure layer thickness early in the process to save material and avoid coating errors? Then coatmaster Flex is your measuring device.

Optimize your production process and protect your coatmaster Flex. If you are not enthusiastic in the first 10 days after delivery, you can return the device for free.

Convince yourself of the performance and save up to 6,000 euros per month of coating material with the coatmaster Flex. Reduce the amount of scrap and improve the quality of production.